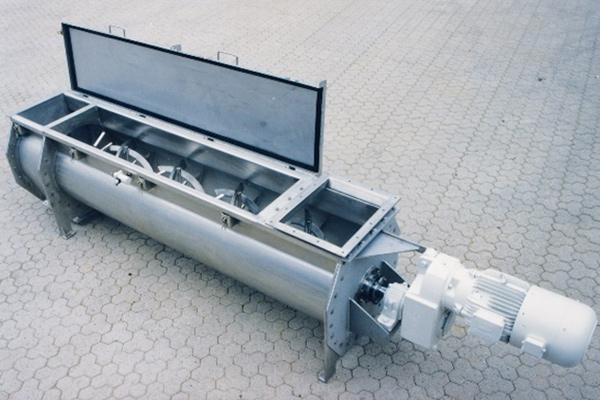

A ribbon blender consists of a U-shaped horizontal trough or shell containing a helical double-ribbon agitator that rotates inside. The shaft of the agitator is positioned in the centre of the trough on which the helical ribbons (also called spirals) are welded. Since the ribbon stirrer consists of a set of internal and external helical ribbons, it is also called a “double” helical ribbon agitator. The counteracting blades are provided for high shear as well as for breaking lumps or aggregates. The ribbon blenders are powered by a drive system consisting of a motor, a gearbox, and couplings. A Ribbon Blender is used for blending large volumes of dry solids, wet solid mass, bulk drug, Chemicals & Cosmetic Powders.

Our Mass Mixer Machines are designed for uniform mixing of wet and dry material especially suitable for Pharma, Ayurvedic & Food Applications. Our Mass Mixer Consists of rigid fabricated structure, mixing drum, stirrer, tilting device & gear box. Special Design mixing paddle is provided to make sure homogeneous mixing of material in the drum.